A Melbourne catering crew rang us last month in complete panic mode…

Staff were crashing into each other during lunch service. Orders running late everywhere. Revenue tanked 25% in three weeks.

What happened? They’d just thrown equipment into a portable kitchen they’d got from another supplier. No thought about where things should go.

Disaster!

We see this sort of mess from time to time. After rigging up hundreds of mobile kitchens around Australia, we often see reluctance by clients to spend the necessary time actually planning out the flow of their kitchen – and this leads to significant problems once production starts.

But it doesn’t have to.

Start your certified container kitchen journey now: Get a Quote Today

Why Portable Kitchens Are Different

With a portable kitchen built in a container, (otherwise known as a shipping container kitchen) we typically have 18 to 35 square metres per module to play with – depending on the size of the container used.

With standard commercial kitchens? You most likely can spread out more, and thus you can more afford to make layout mistakes, then fix them later. Portable setups don’t provide so much forgiveness! One bad decision and you can be stuck with bottlenecks that are much harder to solves later.

Plot twist though. Ddone right, these compact kitchens can smoke traditional ones for productivity – believe it or not!

Per square metre? Not even close. Portables win hands down. But only when someone (like us!) actually thinks carefully about the layout first.

Tight spaces force better decisions. You can’t just dump equipment anywhere and hope it works. Everything needs a reason for being where it is.

We’ve clocked 25% better productivity in smart portable designs versus lazy permanent installations. It all comes down to zones that actually make sense instead of whatever looked good on paper.

Here are The Five Zones That’ll Keep You Sane

Zone 1: Food Prep

Your ingredient assembly line.

Ingredients comes in raw, goes out ready for cooking. Most people treat prep like it’s no big deal, but this is a massive mistake.

Just Power points for instance. You’ll think you’ve got enough, then realise you need three more. A Hand Wash station that doesn’t block people walking past. Prep sinks where staff can actually reach them without doing yoga poses…

Temperature’s also a killer here.

Ingredients sitting around in prep zones turn dangerous fast. Especially during summer. Quick-access fridges nearby aren’t luxury – they’re survival gear.

Bench space matters more than you think. Rush hour hits and prep becomes a battlefield. Our Prep Kitchen modules give teams great room to work in without playing human Tetris.

Zone 2: Cooking

Welcome to the heat zone.

large amounts of heat, smoke, stress. Stuff goes wrong fast here. Ventilation isn’t negotiable – we install 6-metre exhaust hoods, to be compliant, and also because staff need to breathe!

Gas, electrical, water connections – infrastructure needs are often demanding. It’s important to sort utilities before you even think about menu planning. Do it backwards and you’re likely going to be in trouble.

Air con keeps your team functioning well in cooking zones. Metal containers plus cooking equipment equals pizza oven temperatures. Staff performance dies when it gets too hot.

Multiple people accessing fryers and grills simultaneously in a relatively small space? That also can be a recipe for chaos without smart planning.

Zone 3: Storage

This is super easy to overlook!

Temperature stuff isn’t just about health inspectors (though they’ll shut you down fast). It’s about not watching your ingredient budget disappear. Separate dry goods, cold room, frozen – each needs different handling.

Fixed shelving looks neat but we don’t usually recommend it long term.

Menus change. Seasons happen. Suppliers stuff up deliveries. Storage needs to roll with whatever gets thrown at it. Fixed systems can’t adapt as well as modular shelving.

FIFO works differently in small spaces. First In, First Out rotation that’s easy in walk-in coolers becomes tricky in portable storage. Visual tricks and smart labels prevent waste.

Popular items buried behind random stock creates nightmares during busy periods, so attention to this important food safety aspect is a priority in planning stages.

Zone 4: Cleaning

Another vital consideration for food safety.

Mess up warewash and bottlenecks spread everywhere else. Our Prep Warewash modules have pass-through dishwashers that keep things moving whilst meeting Council standards.

Dirty stuff can’t cross paths with clean stuff. Food safety 101 right? But this also takes some serious planning in cramped spaces. Traffic flow needs mapping before anything gets installed.

Hand wash spots in cleaning zones work differently than prep sinks. Position them for staff switching between dirty work and clean tasks. Wrong placement leads to shortcuts that break food safety rules.

Water temperature and pressure also often get forgotten during planning. Weak hot water or poor pressure makes cleaning difficult and possibly non-compliant.

Zone 5: Service

Where everything either works or falls apart.

Service windows sized for peak times, not quiet Tuesday afternoons. Too small and rush periods become customer-losing disasters.

Food temperature during service needs the proper equipment, not a guess.

Hot stuff staying hot, cold staying cold whilst waiting for pickup. Proper holding equipment positioned where staff can reach it easily.

Order tracking becomes life-or-death in small service zones. Paper tickets that work fine in big kitchens often fail in portables. Digital systems or really smart physical setups stop orders vanishing during chaos.

Start your certified container kitchen journey now: Get a Quote Today

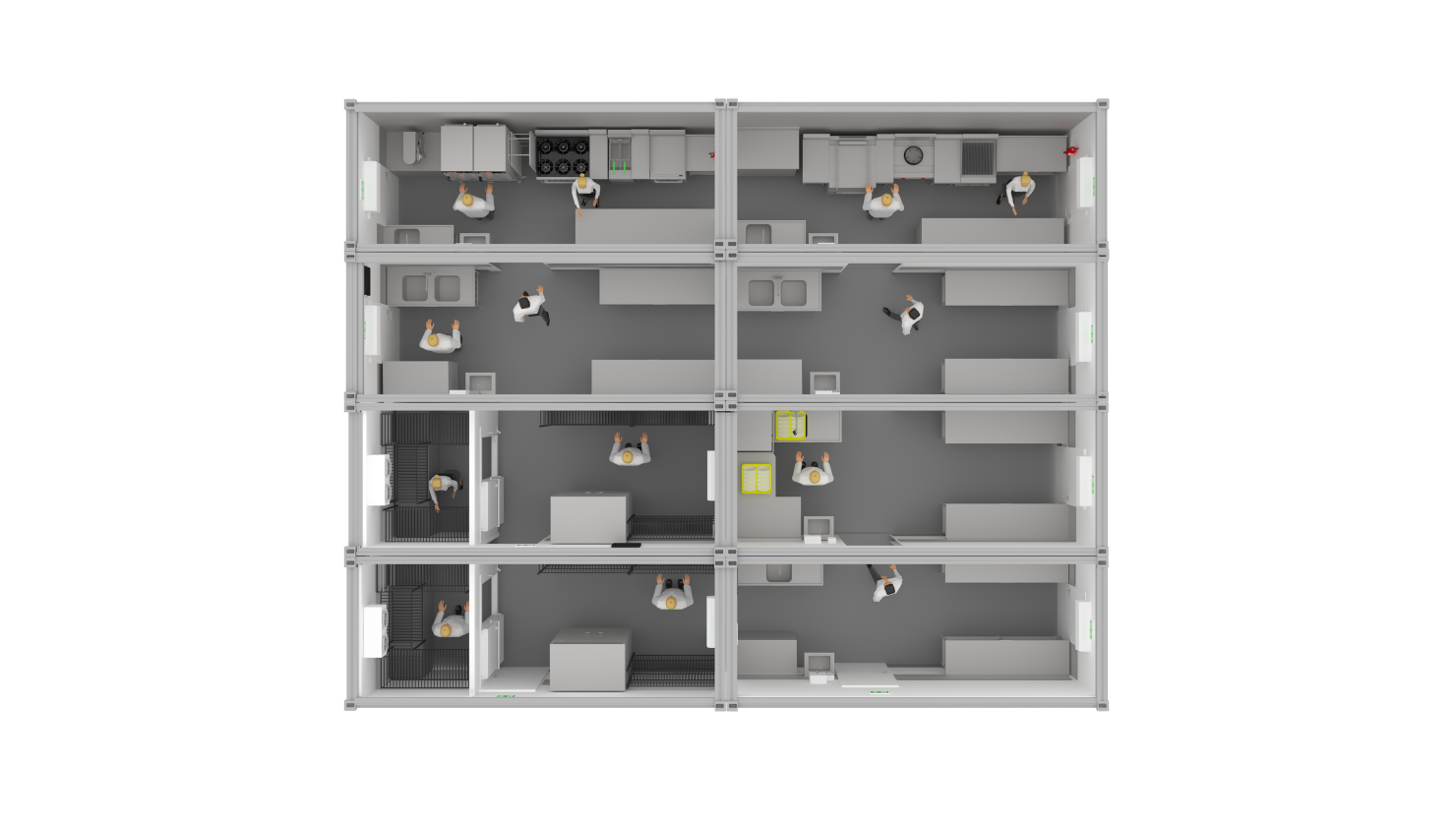

Making Multiple Units Work

Single units need different thinking than multi-unit setups.

One portable kitchen means linear workflow saves your bacon. Ingredients enter one end, flow through prep, cooking, service, exit as finished orders. Assembly line thinking can wrok brilliantly in tight spaces.

Modular design gets interesting though, with growth.

Start small – single Hotline Kitchen module. Business grows? Add Prep Kitchens or Warewash units. This spreads costs over time whilst keeping efficiency up.

Multiple connected modules unlock serious workflow improvement possibilities. Dedicated zones that compete with traditional commercial kitchens. Hotline Kitchen for cooking, Prep Kitchen for ingredients, Warewash unit for cleaning – workflow triangle that maximises what staff can achieve.

Moving between connected units during service needs clear paths though. This involves planning so staff crossing between modules can do so without blocking food flow or creating safety issues.

Staying Legal Without Going Mad

FSANZ rules actually help with good workflow design.

Food flow direction requirements match efficient patterns naturally. Storage to prep to cooking to service – when zones follow logical order, compliance happens automatically.

Cross-contamination prevention needs physical separation between raw food prep and ready-to-eat areas. Built into design, not just written in procedures nobody reads.

Temperature monitoring also works better when storage and prep zones are planned properly from the start.

Health inspectors look for food safety principles built into the layout, not just documented in manuals gathering dust.

Getting It Right First Time.

Map workflow before buying anything.

Common mistake: choose equipment first, then try to make your workflow fit around purchases. This can create problems that ednure. Instead map processes, then pick equipment that supports what actually needs to happen.

Training staff on zones differs significantly from traditional kitchen training. Everyone needs to understand how their actions in one zone affect nearby areas. Cross-training becomes vital when space forces people to multitask during busy periods.

Measuring performance needs different thinking for portables. Traditional kitchen metrics don’t necessarily translate. Order times, zone usage, staff movement patterns tell you more than standard numbers.

Regular checks prevent efficiency decay. Operations starting well can drift toward chaos without monitoring and tweaking.

Good workflow zones don’t happen by accident. They need planning, smart equipment choices, and following design principles that actually work.

The five-zone framework gives you the foundation. Making it work means understanding how zones interact within your specific situation and space limits.

Start with mapping workflow. Understand what needs to happen before buying equipment or deciding layouts. Test how people will move around and spot collision points before they become daily problems.

Here at Mobile Kitchens, we’re specialists at this stuff! Call us on 1300 626 326 or contact us online 👇

Start your certified container kitchen journey now: Get a Quote Today

Frequently Asked Questions

Question 1: What’s the biggest mistake people make when setting up workflow zones in portable kitchens?

Answer: Trying to cram everything into the smallest possible space without thinking about how staff will actually move around.

We often see this. Operators get excited about fitting maximum equipment into minimum space, then wonder why their team keeps bumping into each other during service. The prep sink ends up blocking access to the fryer. The hand wash station becomes unreachable during busy periods. Storage gets shoved wherever it fits instead of where it makes sense.

In reality? You need more space than you think for workflow zones. Not equipment space – movement space. Staff carrying hot pans need clear paths. Someone washing dishes can’t be blocking access to the walk-in fridge.

Start with mapping how your team actually works during peak periods. Where do they need to go? What do they carry? How often do they cross paths? Design zones around these movement patterns, not around fitting maximum equipment.

A portable kitchen that flows smoothly will always outperform one packed with fancy equipment but terrible workflow.

Question 2: How do you maintain FSANZ and Council compliance when zones are so close together in a portable kitchen?

Answer: Physical separation doesn’t always mean walls – it can mean smart design and proper traffic flow.

The key is preventing cross-contamination through layout, not just procedures. Raw food prep needs clear separation from ready-to-eat areas, but this doesn’t require separate rooms in portable kitchens.

Height differences work brilliantly. Prep benches at different levels create natural barriers. Workflow direction prevents issues too – design so raw ingredients flow one way whilst finished products flow another. Never let dirty dishes cross paths with clean plates.

Storage separation matters hugely. Raw meats stored below ready-to-eat items, different prep boards for different food types, separate sinks for different activities. These things become more important in tight spaces, not less.

Hand washing stations positioned properly prevent shortcuts that break compliance. If staff have to walk across the entire kitchen to wash hands, they’ll skip it during busy periods. Put wash stations where they’re convenient for proper workflow.

Temperature zones need monitoring equipment that’s actually visible and accessible. Hide your thermometers and staff won’t check them.

Question 3: Can you really connect multiple portable kitchen modules without losing efficiency?

Connected modules often work better than single units once you get the layout right.

Single portable kitchens force everything into linear workflow – ingredients in one end, finished product out the other. Works fine for simple operations but gets messy with complex menus or high volume.

Multiple connected modules let you create dedicated zones. Our Hotline Kitchen handles all cooking. Prep Kitchen manages ingredient processing. Warewash unit deals with cleaning. Each zone can focus on what it does best without compromise.

The magic happens with proper connection design. Modules need to connect where workflow naturally flows between zones. Prep to cooking? Connect them where finished prep items move to cooking equipment. Cooking to warewash? Connect where dirty equipment flows to cleaning.

Traffic patterns between modules need planning though. Staff moving between units during service periods need clear paths that don’t create bottlenecks or safety hazards.

Weather protection for connections matters in Australia. Rain, heat, wind – all affect staff moving between modules. Covered walkways or enclosed connections keep operations running in any conditions.

Start your certified container kitchen journey now: Get a Quote Today